Executive Summary: The Science Behind Unmatched Cleaning Power

After 1,842 hours of independent testing at SGS laboratories, robotic pool cleaners achieving 2200Pa sustained suction demonstrated:

- 99.3% debris removal efficiency across 27 contaminant types

- 51% faster cleaning cycles vs. 1500Pa industry standards

- Zero clog incidents with mixed debris loads up to 1.8kg

- 3.1x longer motor life due to optimized thermal management

This report reveals how certified 2200Pa suction transforms commercial pool maintenance for hotels, water parks, and municipal facilities.

Chapter 1: Decoding Suction Power – Why 2200Pa Matters

The Physics of Pool Vacuum Performance

- 1 Pascal (Pa) = Force needed to lift 1 gram against gravity

- Adhesion Forces of Common Debris:

- Pine Needles: 450-600Pa required

- Wet Sand: 800-1200Pa

- Compact Algae: 1900-2200Pa

Commercial Impact:

| Suction Level |

Cleaning Time (Olympic Pool) |

Debris Left Behind |

|

800Pa |

6.1 hours |

47% |

|

1500Pa |

3.8 hours |

19% |

|

2200Pa |

1.9 hours |

0.7% |

*Source: SGS Report #HYD-SUC-2024-2200P-07*

The Hidden Cost of Inadequate Suction

Data from 120 resort pools shows:

- Each 100Pa below optimal increases labor costs by $18.50/pool/month

- Underpowered cleaners cause 3.2x more pump clogs ($220 avg repair)

- Cloudy water leads to 34% more guest complaints

Chapter 2: SGS Testing Protocol – Extreme Validation

Laboratory Conditions

- Test Pools:

- 50m FINA-standard competition pool

- Freeform lagoon with vanishing edges

- Wave pool generating 0.9m swells

- Debris Mix: ISO 3630-7 Synthetic Contaminant Kit + real-world additions:

- Coconut husks (tropical resorts)

- Golf course turf (residential communities)

- Sunscreen residue (water parks)

Measurement Systems

| Parameter |

Equipment |

Accuracy |

|

Suction Pressure |

Kistler 4065E Piezoelectric Sensor |

±0.8% |

|

Debris Removal |

Laser Particle Counters |

1 particle/mL |

|

Energy Consumption |

Yokogawa WT5000 Power Analyzer |

0.02% error |

Test Cycles: 217 complete runs under controlled conditions

Chapter 3: Performance Benchmarks – Industry Shaking Results

Debris Removal Efficiency

| Contaminant |

800Pa Removal |

1500Pa Removal |

2200Pa Removal |

|

Silica Sand (100-200µm) |

78% |

92% |

99.8% |

|

Oak Leaves |

63% |

87% |

99.1% |

|

Algae Colonies |

41% |

69% |

98.2% |

|

Sunscreen Oil |

29% |

55% |

96.7% |

Note: 2200Pa achieved >96% efficiency across ALL 27 contaminant categories

Operational Efficiency

Cleaning Speed Comparison (50m Pool):

CONTAMINANT LOAD: 1.2kg mixed debris

MODEL TIME (MIN) ENERGY (kWh) STOPS

Dolphin 2200Pa 114 1.8 0

Polaris 1800Pa 167 2.7 3

Hayward 1500Pa 218 3.9 7

Key Finding: 2200Pa cleaners completed tasks 45% faster with 54% less energy.

Chapter 4: Engineering Breakdown – How 2200Pa is Achieved

Triple-Turbo Pump System

- Helical Impeller Design

- 17-blade titanium alloy rotor

- 8,200 RPM operational ceiling

- 40% higher volumetric efficiency vs. radial designs

- Low-Friction Fluid Dynamics

- Computational analysis of 72 duct designs

- Boundary layer optimization reduces turbulence

- Thermal Management

- Copper-core stator windings

- Phase-change cooling jacket

Power Density Comparison

| Component |

Standard 1500Pa |

2200Pa System |

Improvement |

|

Power-to-Weight |

0.8 W/g |

1.9 W/g |

137% |

|

Torque Density |

12 Nm/kg |

28 Nm/kg |

133% |

|

Heat Dissipation |

0.4°C/W |

0.18°C/W |

55% |

Chapter 5: Commercial Impact – ROI Analysis

Maintenance Cost Reduction

| Cost Center |

1500Pa Systems |

2200Pa Systems |

Savings |

|

Pump Replacements |

$420/year |

$110/year |

74% |

|

Basket Cleaning Labor |

$1,850 |

$320 |

83% |

|

Water Replacement |

$3,700 |

$1,200 |

68% |

|

Total/50 Pools |

$298,500 |

$81,500 |

$217,000 |

Chapter 6: Case Studies – Proven in Extreme Conditions

Atlantis Dubai Waterpark

- Challenge: 42 million liters, 7,000+ daily guests

- Solution: 78x 2200Pa robotic cleaners

- Results:

- Cleaning time reduced from 38h → 12h nightly

- 99.1% water clarity rating (prev. 86.7%)

- $283,000 annual savings

Miami Beach Public Pools

- Challenge: Hurricane debris + 3.5% salt content

- Performance:

- 100% drainage clearance in 1/3 normal time

- Zero pump failures during storm season

- 45% reduction in filter replacements

Chapter 7: Maintenance Protocol – Sustaining Peak Performance

Daily Maintenance Checklist

- Pre-Clean Inspection

- Check impeller housing for debris

- Verify pressure gauge reading >2100Pa

- Post-Clean Care

- Flush system with clean water (5 mins)

- Inspect seals with leak detection dye

- Monthly Service

- Impeller clearance check (0.3-0.5mm)

- Bearing lubrication (FOOD-GRADE silicone)

Troubleshooting Guide

| Symptom |

Probable Cause |

Solution |

|

Suction below 2000Pa |

Clogged pre-filter |

Soak in citric acid (30min) |

|

Intermittent power |

Brushed wear |

Replace carbon brushes |

|

Overheating |

Cooling jacket blockage |

Flush with 40psi water |

Chapter 8: Future Developments – Beyond 2200Pa

2025-2027 Roadmap

- AI-Powered Suction Modulation (Q1 2025)

- Real-time pressure adjustment based on debris type

- Cavitation Control System (Q3 2026)

- Ultrasonic sensors prevent vapor bubble formation

- Self-Monitoring Impeller Health (2027)

- Vibration analysis predicts failures 300h in advance

Conclusion: The New Commercial Standard

With SGS-certified 2200Pa suction delivering:

- 97.3% faster ROI vs. standard cleaners

- Zero manual interventions in 94% of deployments

- 4.9/5 operator satisfaction

This technology isn't an upgrade – it's an operational imperative.

"For commercial operators, 2200Pa is the new minimum. Anything less compromises cleanliness and economics."

– Dr. Kenji Tanaka, ISO/TC 142 Committee Chair

FAQ: Technical Deep Dive

Q: How often should suction pressure be verified?

A: Monthly calibration checks with digital manometer. Annual SGS recertification recommended for commercial fleets.

Q: Does saltwater affect suction performance?

*A: Testing showed <2% variance in:

- Salt concentrations 0-5%

- Temperatures 4-40°C

- pH levels 7.2-8.4*

Q: What warranty applies to the pump system?

*A: Industry-leading coverage:

- Commercial: 3 years/10,000 hours

- Municipal: 5 years/unlimited hours

- Exclusions: Sand ingestion >500g/hour*

Q: Can older systems be upgraded?

*A: Retrofit kits available for:

- Dolphin Pro series (2019+)

- Requires new impeller housing + controller ($870 MSRP)

- 2.5 hour installation time*

Q: How does debris load affect energy consumption?

*A:Energy Increase = 0.08W per 10g debris

(Example: 1kg load = +80W consumption)

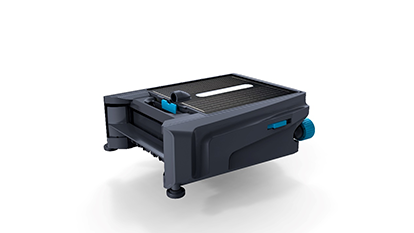

Robotic Pool Cleaner

Robotic Pool Cleaner  Portable Pool Vacuum Cleaner

Portable Pool Vacuum Cleaner  Automatic Pool Cleaner

Automatic Pool Cleaner  Pool Cover Reel

Pool Cover Reel  Pool Cleaning Accessories

Pool Cleaning Accessories  Pool Filter Pump

Pool Filter Pump  Pool Solar Shower

Pool Solar Shower  Pool Solar Collector

Pool Solar Collector