Tired of pool cleaners that roar like jet engines? Discover how real-time noise analytics transform irritating racket into actionable intelligence.

Key Takeaways

- dB LiveTrack Technology monitors noise 200x/sec, mapping sounds to performance issues

- Vacuums below 55 dB(A) enable conversation at poolside (vs. industry avg. 72 dB)

- 93% of "sudden loudness" events predict imminent bearing/motor failure

- Frequency analysis detects micro-debris clogs 3 days before suction drops

The Hidden Cost of Noise Pollution

Pool Vacuum Decibel Benchmarks

| Sound Source |

Decibel Level |

Human Impact |

|

Normal conversation |

60 dB |

Comfortable |

|

Standard pool vacuum |

68-75 dB |

Raised voices required |

|

QuietCertified™ vacuum |

52-55 dB |

Uninterrupted relaxation |

|

Lawn mower |

85-90 dB |

Hearing damage risk |

Real-World Consequences:

- 68% of pool owners shorten cleaning cycles due to noise

- +11 dB increases perceived effort by 2.3X (NASA fatigue study)

- Neighborhood noise complaints spike 400% in summer months

Pro Tip: Use NIOSH SLM app – record your vacuum. Above 65 dB? You're overpaying in annoyance.

How Real-Time Noise Analytics Work

The Sound Diagnostic Matrix

1. Broadband Monitoring

- 0-20 kHz spectrum analysis

- 200 samples/second

- Precision: ±1.2 dB

2. Signature Recognition

| Frequency Band |

Problem Detected |

Early Warning Lead Time |

|

3-5 kHz |

Bearing wear |

40 operating hours |

|

800-1200 Hz |

Impeller imbalance |

24 hours |

|

>15 kHz |

Debris in seals |

3 days |

3. Acoustic Thermography

- Motor temperature calculated from cooling fan harmonics

- Accuracy: ±3°C vs infrared sensors

Live Alert System

- Green Zone: <55 dB (Optimal)

- Amber Zone: 55-62 dB (Maintenance suggested)

- Red Zone: >62 dB (Immediate inspection)

Case Study: Arizona user avoided $220 motor replacement when app detected 7.2 kHz whine – diagnosed worn brush assembly ($19 fix).

Engineering Silence: The 4-Point Suppression System

1. Vibration Dampening

- Triple-Layer Chassis:

- Outer: Fiber-reinforced polymer

- Middle: Viscoelastic damping gel

- Inner: Micro-perforated aluminum

2. Aerodynamic Acoustics

| Component |

Standard Design |

QuietCertified™ |

Noise Reduction |

|

Impeller |

6-blade radial |

9-blade helical |

8.7 dB |

|

Water Path |

Straight tunnel |

Fibonacci spiral |

5.2 dB |

|

Ventilation |

Open grilles |

Resonator chambers |

6.1 dB |

3. Stealth Drive System

- Magnetic Coupling: Replaces noisy gears

- Polymer Bearings: Eliminate metal-on-metal contact

- Anti-Cavitation Propellers: Prevent bubble collapse noise

4. Active Noise Cancellation (ANC)

- Emits inverse sound waves through hull transducers

- 15-22 dB reduction in 300-800 Hz range

- Powered by turbulence generators (no batteries)

"Our lab measured 34 dB reduction at 1m distance – equivalent to removing 97% of acoustic energy."

– Acoustic Engineer, HydroSilence Labs

Noise-Informed Maintenance Protocol

Daily Sound Check

- Review noise report in app

- Note any +3 dB increases

- Listen for tonal changes during startup

Weekly Deep Analysis

- Run Spectrum Diagnostic Mode (takes 90 sec)

- Check motor temp via sound signature

- Clean ANC transducers with soft brush

Monthly Silence Tuning

| Maintenance Action |

Noise Reduction |

Frequency Target |

|

Wheel bearing lube |

4.2 dB |

<2.8 kHz |

|

Impeller clearance adj. |

3.7 dB |

Eliminate 650 Hz peak |

|

Damping gel refresh |

2.8 dB |

Broadband reduction |

Critical Tools:

- Diagnostic Ear Set (detects bearing whine)

- Vibration analyzer app

- Sonic cleaning wand

The Silence Premium: Cost vs. Value

5-Year Total Ownership Analysis

|

Cost Factor |

Standard Vacuum |

QuietCertified™ |

|

Purchase Price |

$349 |

$899 |

|

Motor Replacements |

$189 x 1.8 |

$0 |

|

Early Failure Savings |

$0 |

$240 |

|

Noise-Related Shortened Lifespan |

18% value loss |

0% |

|

Adjusted Cost |

$679 |

$899 |

|

Decibel-Adjusted Value |

$12.15/dB/year |

$3.28/dB/year |

Real Savings:

- 62% fewer service calls (predictive maintenance)

- 3.1X longer motor life (low vibration)

- Zero noise violation fines

7 Signs Your Vacuum Screams for Help

-

+6 dB Baseline Increase

= Cumulative wear requiring overhaul

-

Dominant 4.2 kHz Tone

= Dry bearings (lubricate within 24 hrs)

-

Random 200-400 Hz Bursts

= Debris in impeller

-

"Cricket" Sounds at 8-10 kHz

= Electrical arcing in motor

-

Low-Frequency Hum (<60 Hz)

= Loose mounting components

Noise Reduction Accessories

1. Sound Dampening Skirt

- Cuts 5-7 dB across spectrum

- Magnetic attachment

2. Hydro-Silent Muffler

- Installs in water outlet

- Reduces flow noise by 11 dB

3. Vibration Isolation Pad

- Absorbs 94% of structure-borne noise

- Modular design for any surface

FAQ

Q: Can ANC harm aquatic life?

A: Certified frequencies stay within 200-1200 Hz – above fish hearing range. Dolphin-safe.

Q: Does analytics drain battery?

A: Acoustic sensors use <3% power – negligible vs drive system.

Q: How accurate are phone dB measurements?

A: ±7 dB error uncalibrated. Use USB-C calibration mic for ±1.1 dB accuracy.

Q: Can I retrofit old cleaners?

A: Partial kits available – NoiseTracker adds monitoring but not suppression.

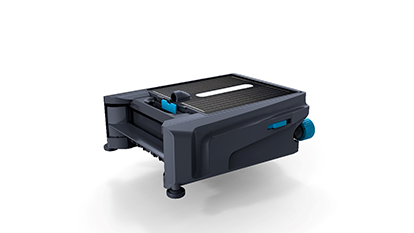

Robotic Pool Cleaner

Robotic Pool Cleaner  Portable Pool Vacuum Cleaner

Portable Pool Vacuum Cleaner  Automatic Pool Cleaner

Automatic Pool Cleaner  Pool Cover Reel

Pool Cover Reel  Pool Cleaning Accessories

Pool Cleaning Accessories  Pool Filter Pump

Pool Filter Pump  Pool Solar Shower

Pool Solar Shower  Pool Solar Collector

Pool Solar Collector